Thomas W. Krause; Aroba Saleem; P. Ross Underhill

Abstract

Ferromagnetic iron based alloys are used in many important steel products including electrical steels, oil and gas pipelines, naval structures, aircraft landing gear and automotive components. Magnetic properties of these materials are vital for such applications as electrical motors and transformers, ...

Read More

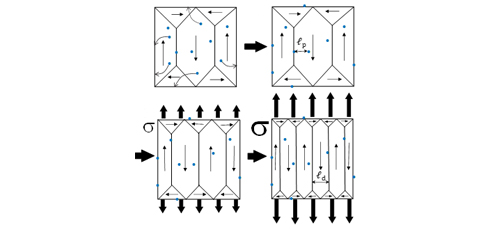

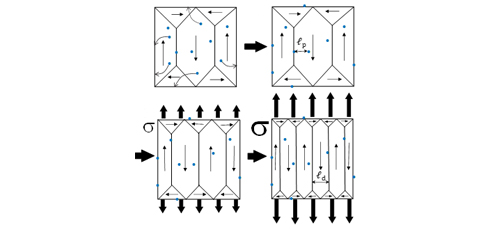

Ferromagnetic iron based alloys are used in many important steel products including electrical steels, oil and gas pipelines, naval structures, aircraft landing gear and automotive components. Magnetic properties of these materials are vital for such applications as electrical motors and transformers, where they have direct implications for energy efficiency. Many inspection methods rely on measurement of magnetic response including magnetic particle inspection, magnetic flux leakage, metal magnetic memory, magnetic adaptive testing and magnetic Barkhausen noise (MBN). Understanding the dependence of magnetic properties on material condition is particularly important for detection of residual stress using MBN. This paper examines MBN response in a high strength naval steel, Q1N, undergoing magnetization, including domain structure, which is modified by application of tensile stress, and its interaction with pinning sites within grains, as provided by impurity elements and carbides, whose density is varied by isothermal tempering treatment. A physical basis for modifying domain structure and experimentally examining its interaction with changing pinning site density via temper embrittlement is presented to investigate stress dependent behaviour of MBN in such steel materials. The introduction of this experimental process will facilitate the potential of MBN sensing technology for advanced monitoring of steel structure condition.

Thomas W. Krause; P. Ross Underhill

Abstract

Eddy current (EC) technology for inspection of conducting materials is a potential solution when conditions preclude the application of other methods. Such conditions include presence of sound absorbing coatings, unavailability of a couplant, multiple conducting layers with air gaps, limited access or ...

Read More

Eddy current (EC) technology for inspection of conducting materials is a potential solution when conditions preclude the application of other methods. Such conditions include presence of sound absorbing coatings, unavailability of a couplant, multiple conducting layers with air gaps, limited access or near surface cladding. However, the choice of a particular EC technology may not be clear due to sources of electromagnetic interference, choice of probe design, target configuration or even available equipment. In addition, the choice of EC based technologies is extensive, including conventional EC, low frequency EC, remote field EC and pulsed EC. Each of these technologies has its own challenges and limitations, which need to be considered prior to a commitment to system development. Probe choice becomes a function of the particular technique that has been selected and may include ferrite core sensing coils, GMRs or eddy current coil array. Finally, EC signal analysis methods need to be selected based on effects of potentially multiple varying parameters. This paper examines the potential of electromagnetic inspection technology, discussing its limitations, effects of common essential parameters and analysis methodologies. Examples of recent technology applications are given and the benefits and limitations of various technologies are compared and discussed.